Easy handling

Mininfra SmarT SW® grain analysers are very easy to use for even a non-skilled average user: thanks to its hopper no sample preparation is needed and the analysis can be started by pressing a button on the large colour touchscreen of Mininfra SmarT SW®.

Stability and reliability

Due to the applied measurement technology and robust calibrations the accuracy and repeatability of Mininfra Smart SW® grain analysers satisfy today’s high requirements thus Mininfra Smart SW® is a reliable device on all application areas.

Internet connection

Mininfra SmarT SW® grain analysers can be connected and managed through the internet. With the client software to be installed to a PC you can read out the measurement data, statistics remotely and also you can upgrade the newest software versions and the calibrations of the devices from a remote location.

Calibrations

Mininfra SmarT SW® grain analysers are delivered with all available calibrations for whole grain.

Specific weight module

Mininfra SmarT SW® contains an additional test weight module too. The instrument can test the specific weight os wheat, barley, corn and soybean: besides the common parameteres of the crops you can get a reliable hectoliter weight result within the same analysis process.

Portability

The small size and light weight of Mininfra Scan-TPlus® grain analysers make it possible to use the device on more locations, on the farm, or even on the field. Mininfra Scan-TPlus® is delivered with a metal case in order make the transportation safe and easy. The device can be operated at 12V power supply too, e.g. powered by a common cigar lighter of a car.

User friendly interface

The large, colour touchscreen of Mininfra Scan-TPlus® grain analyser as well as the clear and logical menu system make the everyday use of the device very simple.

Sample handling

For different kinds of grains (different kernel sizes) belong different sample holders (cuvettes) for sample presentation. The sample holders of Mininfra Scan-TPlus® are robust, easy to fill, empty and clean.

Calirations

Mininfra Scan-TPlus® grain analysers are delivered with one 18mm sample holder and calibrations for wheat barley, rye, durum, etc. by default. Further calibrations and sample holder are optional according to the table below:

Product |

Cuvette |

Width (mm) |

|

Wheat, Rye, Durum, Triticale |

A |

18 |

Default |

Barley |

G |

16 |

Default |

Sunflower seed (hulled)* |

A |

18 |

Optional |

Corn |

B |

30 |

Optional |

Flour, soymeal |

C |

4 |

Optional |

Rapeseed |

D |

8 |

Optional |

Soybean, rice |

E |

26 |

Optional |

Durum flour |

F |

7,5 |

Op |

Falling device number,

Technical Information :

Measurement of the enzyme alpha-amylase natural

Testing Fvngal

Operation in accordance with the standards iso-aacc-icc

A thermal printer

Keyboard with anti-friction coating

Dimensions: 545 * 458 * 187

Weight: 32 kg

Power supply: 230 V

Warranty: Two years and ten years after sales service

Gluten dryer

Technical Information

Determine the water absorption of the samples have the same value in the wet gluten

Measure dry gluten 150 ° C for 4 minutes.

Page has three optical warning include: on-off-power

Control by microprocessor

The device automatically adjust the operating time

Sound signal the end of each test

Dimensions: 230 x 90 x 180 mm

Weight: 108 kg

Power Supply: 220 Watt

Warranty: Two years and ten years of service after sale

Hp devices liters

Technical Information :

Measuring test weight grains such as rice, wheat, Zdt, lentils

Flour yield estimate of the weight

Equipped with a digital scale with decimal point precision

Dimensions: 90 x 410 x 180 mm

Weight: 3.5 kg

Warranty: Two years and ten years after sales service

Primeroll Rollermill

Technical Specifications

Useful Model Certified Driving Belt Tensioning System

Minimum Energy Consumption with New Driving Belt Tensioning System

New Reformed Long Lived Feeding Drive System

Fast and Easy Mechanical Equipment Change, Roll Maintenance and Changing Feature

Maximum User Safety

Automatic Roll Adjustment Option

Atex Certified Roller Mill Option

Product Inlet Part is more functional and easier to be Followed

New generation feeding system and special applications

Stainless Steel Option

Purifine Semolina Purifier

Technical Specifications

· Innovative & Modern Design· More Linear Movement Thanks To New Designed vibration chock

· More easier cleaning and mechanical equipment maintenance thanks to easy dismantling of front parts

· Maximum Hygienic sifting section and discharging tray

· More sifting area thanks to new developed sifting frames

· New developed Air Aspiration System

Grandsifter Square Plansifter

Technical Specifications

FUNCTION AND FEATUREThe Square Plansifter is a machine that plays a very important role in the process of producing flour. It is used for the sifting and classifying of grinded grain that comes from the Roller Mill. The sifting process is arranged according to the milling diagram.

The plansifter consists of following main parts;

•Two parts of sifter frame compartments

•chassis (Driving Section)

•Swinging parts on both sides

The compartments are connected to the chassis with bolts so that the plansifter gets hang to the ceiling with wag parts. The plansifter is designed for sifting various grains, rye, maize and also drum mills.

- Net sifting area of 24 to 120 m² depending on the type of sieves,

- Steel construction

- Intensive motion for gaining maximum capacity

- Up to 14-28 sieve per compartment

- Wood sieves with coated formica

- Noiseless and efficient sieve cleaning

- Sieve trays of tih plated steel sheet, (option : formica)

- Easy changing of frames regarding to requirement

- Easy cleaning

- Minimum maintenance, optimum sanitation

- partial loading for easy transport

WORKING PRINCIPLE

The plansifters are used in;

- Flour Mills

- Semolina Mills

- Maize, rye, oat Mills

- In every kind of Grain

ADVANTAGES

Grandsifter square plansifter and the products with the same strong specifications have wide sifting area due to their aliminium telora and specially imported tapotens.These machines have %25-30 more sifting area compared to standart sifter.

Grandsifter frame and aluminium Telora Practice . Easy running with new cleaners and wireless type.

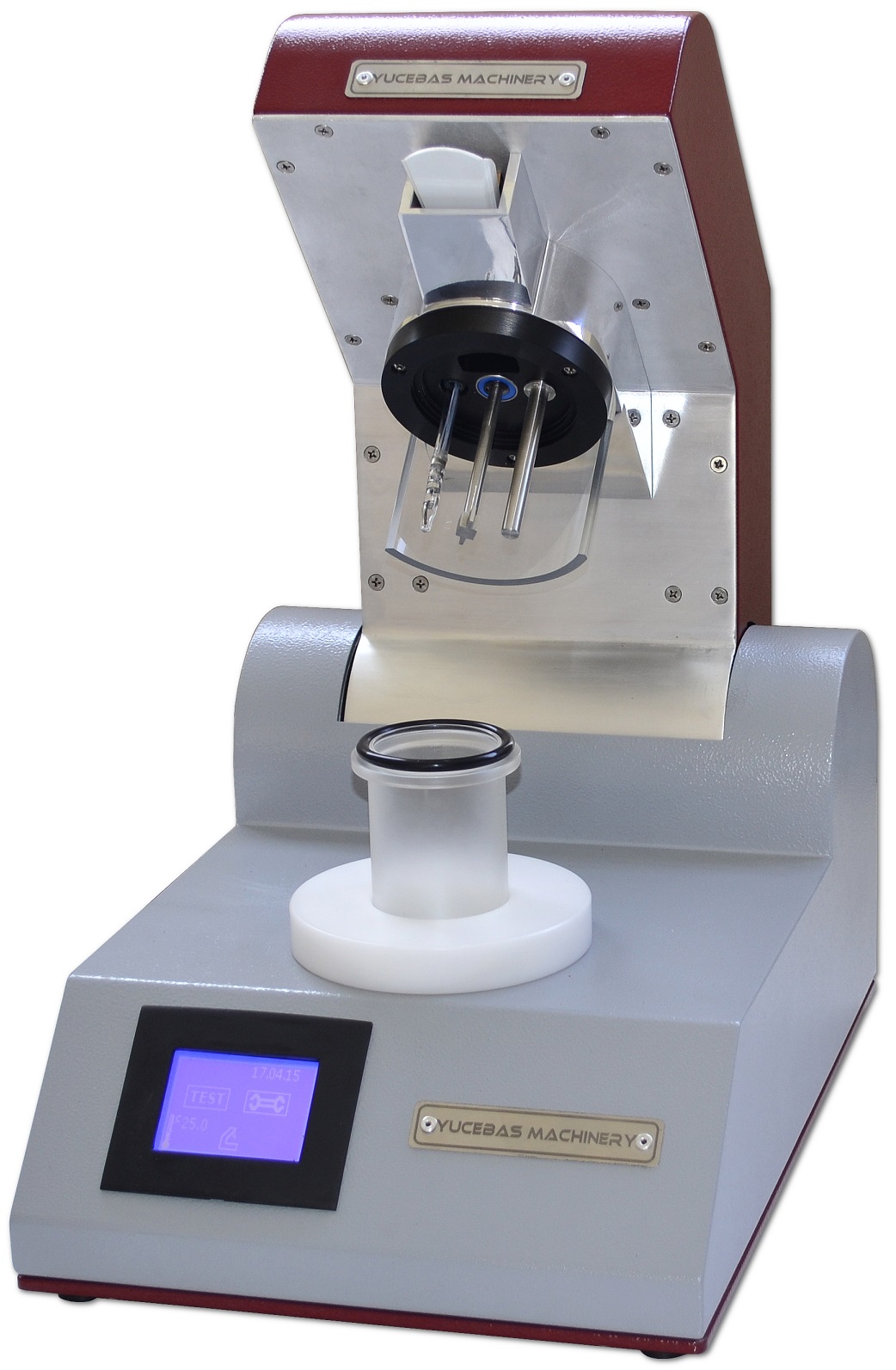

The resistance and extensibility abilities are the most important parameters of the dough. YÜCEBAŞ MACHINERY DOUGH TESTING DEVICE is a device use for the dough pieces weighed 150 gram, will be stretched special hooks of the equipment on 45 , 90 and 135 minutes respectively. Dough Testing Device gives similar results as Extensograph. The device has it’s own embedded industrial PC and own software. The device can control directly from the touch screen industrial PC. The dough shaping unit and stretching hook of the equipment can be control from touch screen PC. Use of software of the device realize the calculations for the evaluation of the curves.

Dough Testing Device can be determine :

- Resistance of 5th minute ( R5 )

- Maximum resistance ( Rmax )

- Elasticity ( mm )

- Maximum resistance ( Rmax )

- Energy ( cm2 )

Vitamin Dosing Machine dosages between 1 and 50 gram product at 1 minute. Dilutation the vitamin with another product is not necessary. CHROMIUM materal is used in the vitamin dosing machine. Private mixer is in the bunker part. Vitamin Dosage Machine is formed from two parts for product dosage. The first part is feeder. This part is feed the product 20 gram to bottom feeder. Bottom feeder carries approximately 1 gram product on every department, for this reason dosage procedure can be more sensitive. This product is checked with potentiometer. Maximum dosage is 100 gram product in 100 Hz. You can dosage 50 gram product in 50 Hz, 25 gram product in 25 Hz. and 12,5 gram product in 12,5 Hz. The product dosage as pruverize. Mix substance is dosage as scattered dust.

YUCEBAS MACHINE WHEAT CLEANING DEVICE (TRIEUR SYSTEM) separates the foreign material from wheat. Products are accumulated on the pots. These pots are underside of the device You can separates the corn with the alternative sieves. The followings are separated sequentially. Depending of the different sieves other cereals can be seperate.

1 - Slim Pieces from under of 2,2 mm Sieves, Dust and Straw

2 – Foreigner Seeds

3 – Broken Pieces and Kernels

4 - Whole Pieces

5 - Big Foreigner Material

YUCEBAS MACHINERY SINGLE SPIKE HARVEST DEVICE separates the products from single spike of grain like as barley and wheat. The instrument blends the spikes of grain or 5 kg. spikes of grain's group. Energy cable has owns pulley system. When blend's lid is opened, automaticly protection starts and system stops as automatically. Air's locks are on the device for better separate. Vessel for end of the product, vessel for dust and straw's bag are on the device. Fitting on a special platform with tyres.

YUCEBAS MACHINERY WET WHEAT GRINDING MACHINE consists of two sections. The first section is the right side (breaking side) of the machine and composed of two collecting reservoir. The second side, the left side has single collecting reservoir. The mill is designed from the ease of operation and follow-up, occupation of minimum space at the laboratories. The cleaning, maintenance and the assembly / disassembly of the rollers, and the control could be done easily by hand. The rollers are hardened up to 50-55 HRC. The breaking and smooth reduction rollers are manufactured by using special tools to the 0% error from the special steel material. One of the other properties of the machine is the usage of the inert material during the production. The flour (B1-B2-B3, C1-C2-C3), coarse and fine bran are received from 6 channels through the 3 breaking rollers and 2 reduction rollers with 160 μ - 800 μ - 160 μ sieves respectively. YM1 Wet Wheat Grinding Machine gives similar results as CD1 Mill. The mill provides the determination of the yield of the milling plants as well.

The mixing ratio of different wheat varieties by the flour production, flour quality and effects of some additives (ascorbic acid, cellulatic enzymes, oxidation enzymes) can be determine with RHEOGRAPH device. With the device, constant pressure to inflate the dough with the resistance (P), elongation (L), energy (W) values can be determined. In a short time dough quality characteristics can be obtained with the device. Rheograph gives similar results as Alveograph. The device has it’s own embedded industrial PC and own software. The device can control directly from the touch screen industrial PC. All test results calculate and record on the industrial PC of the device.

Rheograph can be determine :

-Resistance/Maximum Resistance to Pressure (P)

-Extensibility-Curve Length (L)

-Energy (W)

-P/L

-le (Elasticity Index)

YÜCEBAŞ MAKİNE OTOMATİK SU DOZAJ SİSTEMLİ UN TEST CİHAZI Hamurun yoğurma sırasındaki reolojik özelliklerinin belirlenmesinde yararlanılan ve unun ekmeklik özellikleri hakkında çok geniş bilgi veren bir cihazdır. Bu cihazda hamurun yoğurma sırasında yoğurucu paletlerine karşı gösterdiği direnç, çizilen kurveler cihaz üzerinde gömülü bulunan endüstriyel PC'nin bünyesinde bulunan kendi özel programı vasıtası ile kaydedilir. Cihaz direk olarak bünyesinde gömülü bulunan dokunmatik ekranlı endüstriyel PC üzerinden kontrol edilir. Cihazın 0-200 devir arasında ayarlanabilen dinamometresi mevcuttur. Farinograf cihazı ile eşdeğer sonuçlar vermektedir. Cihaz un numunesine su verme işlemini bünyesinde bulunan dokunmatik ekran PC kontrollü su dozaj sistemi ile otomatik olarak yapmaktadır. Mikser içerisindeki hamur numunesinin ve dozajlanacak suyun sıcaklığı lcd ekran üzerinde izlenebilmektedir. Hamurun tüm özellikleri endüstriyel PC üzerinde ölçülür, hesaplanır ve kaydedilir.

YUCEBAS MACHINERY GLUTEN DRYER is dried the samples at 150°C during 4 minutes . After drying the gluten is weighed on the balance. Gluten Dryer gives similar results as Glutork. It' s a short and practical methods for flour factories.

YUCEBAS MACHINERY BRAN BRUSHER is a equipment using for seperate successfully from coarse bran to flour and semolina. Sieves by aid of the wind palletized system thus separates the flour and semolina remained on the bran. Obtained data will be useful for calculation real % ratios.

Damaged Starch Analyser is based on working with an amperometric method in order to measure the starch damage in flour samples. Damaged Starch Analyser gives similar results as SDMatic. The device measured the amount of iodine absorbed by starch granules in a diluted flour suspension with special solution. The test performs 1 g of flour sample aprrox. in 7 minutes. The necessary iodine is generated by the special probe of the device in order to determine the iodine absorbtion. Test results are expressed as % of the iodine absorbtion. The more absorbtion of the iodine means more damaged starch.

Main applications of the measurement of damaged starch are;

* Quality control of the flour

* Control the settings of the rollers in the mill

* Improve dough yield by adjusting water absorption ratio

* Adjust the stickiness of the dough

YÜCEBAŞ MACHINERY SEDIMENTATION DEVICE determines the wheat bug damage in the wheat and flour samples. If there is a bug damage in the wheat, the sedimentation values will be low and it means lower protein quality.

Sedimentation Device works for 5 minutes according to the analysis principle. The user’s can do the tests with 6 different samples at the same time. There is not any button on the device for control of device. The device can directly control from touch screen LCD. The device is suitable for Sedimentation Test and Modified Sedimentation Test. The user’s can do the Sedimentation Test during the resting period of Modifed Sedimentation Test. The user’s can see the resting period of Modified Sedimentation Test as minute on the touch screen LCD, when they do another Sedimentation Test. The test period, shaking number, internal temperature of device, date and time can be see easily on the screen.

Disc Mill is available for grinding grains, wheat, malt, barley, pea, corn, pellet, soybean and other products. The samples are rapidly grinded between sharp steel discs. The distance between the discs is adjustable for providing particle size distribution. The disc mill has robust design and low noise. The discs are designed to prevent the heat development during the grinding procedure. All grinded material is collected on the 250 ml cups.

The Disc Mill is suitable for preparing samples for moisture determination, particle size index and NIR protein analysis. The mill is able to grind the materials, which has lower than 20% fat content. Disc mill can grind 50 g samples in 15 - 20 seconds (depending on the moisture content and density of the sample).

YUCEBAS MACHINERY FALLING NUMBER DEVICE is operating in compliance with both Classical Falling and Fungal Falling Number methods. It has a PIC control, Touchscreen LCD, dual tube systems and standart printer. There is not any button on the device for control of device. The device can control directly from the touch screen LCD. The test period, temperature of water bath, date and time can be see easily on the screen. You can see the average account for two different sample end of the test at the same time. The device adjusts the boiling point automatically according to the altitude of the laboratory. The device can calculate the test results automatically according to the altitude for FN (Method 1). A water circulation system, which is going to fix the steam pressure as constant, installed on the housing of the bath, in order to eliminate the loss of water as steam to be installed at the water bath of the device. In order to personal protection of potential heat damage of technical person, equipment donated with a special protector.

Device is used for find the real value of product according to quality of production. Maximum capacity is 1 kg (approx in 10 minutes) for cleaning procedure. The followings are separated :

1 – Dust and Straw

2 – Thin and Broken Grains

3 – Whole Pieces

4 – Big Foreign Materials

YUCEBAS MACHINERY GRAIN CLASIFICATION DEVICE can be use in order to determine partical size of diffent cereals like wheat and barley in milling and malting-brewing industries. Grain Classification Device works with cleaned sample as 100 gram. The running time can be chosen from controll box. PIC controller is on the device. Different samples are classificationed with different sieves. This sieves can be exchanged as easily. Long perforated sieves are on the devices as standart accesories. The measurements of the sieves's are 2,8 mm - 2,5 mm and 2,2 mm. Grain Classification Device works as suitable according to MEBAK - EBC - ICC methods. 4 different samples are taked on end of the test. This samples are upper surface of 2,8 mm sieves, upper surface of 2,5 mm sieves, upper surface of 2,2 mm sieves and under surface of 2,2 mm sieves. Optionally different size of sieves can be obtained.

WHEAT CLEANING DEVICE WITH TRIEUR SYSTEM separates the foreign material from wheat. Products are accumulated on the pots and weighed by loadcell. These pots and loadcells are underside of the device. You can separate the corn with the alternative sieves. Depending of the different sieves other cereals can be seperate. The followings are separated sequentially.

1 - Slim Pieces from under of 2,2 mm Sieves, Dust and Straw

2 - Foreigner Seeds

3 - Broken Pieces and Kernels

4 - Whole Pieces

5 - Big Foreigner Material

YUCEBAS MACHINERY SUNFLOWER SEED SORTING MACHINE is used to determine the amount of seed purchased the product fast seed extraction mechanism. Also, seed breeding and seed companies engaged in the study to use this machine.

The Sunflower Seed Sorting Machine has 3 motors.

1- Peeler (scraper) motor

2- Air-lock movement motor

3- Air extractor motor

This machine is separates seeds with the assist of rotating in the opposite direction of scraper spirals and the clamping unit. Foreign matter is removed by the air intake from the seed. As the result, only seeds collected in the storage tank.

Yucebas Machinery Diastograph determines the gelatinization properties and enzyme activity of flour, whole flour meal, rice flour, maize, rye and barley etc. Diastograph gives similar results as Amylograph and Viscoamylograph. The working principle of the instrument is that a suspension of flour and distilled water is heated with a constant rate 1.5 °C/min with the rotating bowl where the strength against the mixing is measured considering the viscous characteristics of the sample.

The Diastograph can control directly from its embedded touchscreen industrial panel PC. The device equipped with two step motors to control the mixing bowl and mixing head. The temperature control of the device can adjust and follow from its software.

The Diastograph can determine following parameters:

- Maximum gelatinization

- Viscosity in the beginning

- The temperature of the beginning of gelatinization

- Hot / Cold phase viscosity

- The temperature of gelatinization

YUCEBAS MACHINERY WHEAT HUMIDIFICATION MIXER is used for mixing of the wheat, flour and additives ensures optimal conditioning and homogenisation of the products in the pre and post milling stages.

- Conditioning of the wheat before milling.

- Mixing of the flour after milling.

- Mixing of the additives.

- Preparation of the wheat or flour mixtures.

YUCEBAS MACHINERY SIEVE SHAKING DEVICE has 8 parts sieves. Sieve's frames size are 200 Ø and made from special PVC. The sieving system works on circular motion. The system controlled by digital timer. Operating time can be changed on the digital control panel. Different sized sieves can be montage according to customer demand.

This mill was made as soundproof. There is a metallic grinding circle. The sample comes to this part with air flow feeder. Hardened steel hammer forces the samples for passing to steel sieves with rotation rate 16.800 rpm. Sample is crushed as homogeneous and accumulated in the rustproof vessel. Optional motorized feeder can be added the system for consistent feeding. Standard sieves ( 0,8 mm ) are used for falling number, Gluten washing device, Gluten centrifugal and NIR analysis. There are more 2 different sieves ( 0,5 - 2,0 mm ).

There is no need the cleaning between two samples. The samples can be grinds with slow feeding up to 25% moisture content. The flow rate of automatic feeder is adjustable. The Hammer Mill is designed with security cover switch.

YUCEBAS MACHINERY COMBINED MILLS achieves to grind the tempered and non-tempered wheat samples then sieves by aid of the wind palletized system thus separates the flour remained on the bran. The device combined with 5 rollers (3 breaking and 2 reduction). There is no need to clean the mill before processing another wheat sample for following any process of the mill by reverse turning of the switch of sieving unit, the bran or any similar substance remained on rollers and sieve of the mill are discharged from the front discharging outlet through wind pallets system. In order to asses the grinding capability of the wheat, to use a mill having a grinding capability ensuring no plugging on sieves and ensuring many advantages related to the ash quantity and the color of the flour is preferred for a useful flour sample. As a result the grinded flour sample and the bran can be obtained from the mill without any loss. Therefore, by weighing the flour sample and the bran the productivity is possible to be found easily and correctly.

Trying to obtain the flour over the flour percent given by the wheat causes an increase of the bran quantity so the ash quantity in flour, index value, gluten quantity and dough resistance increase. It means that the correct process is to identify the flour productivity of used wheat instead of the productivity of a mill. To obtain the flour from the wheat is very important from the point of the view of the other experiments producing the correct values

YÜCEBAŞ MACHINERY Tube Shaker of the Falling Number Device can work with the two samples at the same time and it makes ready your samples for the Falling Number Tests and Fungal Falling Number Tests. The shaking time of the device can be adjust between 2 and 15 seconds.When the covers of the device open during the shaking,the device stopped automatically with the safety covers.

YUCEBAS MACHINERY DRYING CABINET is used for drying the products. This cabinet has temperature and Rh controller. Temperature and Rh can adjustable for desired values .

Vitamin Dosing Machine is designed to provide addition/dosing of the flour additives to the raw material in accurate amounts after the milling/sieving process. The device is manufactured by stainless steel material. The device has the gear motor connects to speed control unit, cooling fan, screw conveyor and a special mixer on the bunker part. The device provides the dosing of flour additives such as ascorbic acids, glucose oxidase, filling materials etc. in accurate amounts as 1.2 kg/h – 10.5 kg/h considering the density of the additives with the different varieties of the screw conveyors and adjustable speed of the motor from the speed control unit of the device to the final product.

COLOR AT FIRST SIGHT

Ultimate: high resolution TRICHROMATIC FULL COLOR RGB sorter with integrated shape-sizing system.

Technological: image acquisition using HSI technology to see almost as a human eye. Additional NIR and InGaAs cameras available (option)

Precise: SEA-CHROME software can recognize up to 16 families of defects. Optical resolution 0.1mm

Max Capacity: highest production capacity RGB trichromatic sorter with 1 to 7 chutes models

Flexible: Multichannel models divisible in 4 complete independent sections (4 sorters in 1)

Reliable: thanks to over 40 years’ experience in electronic sorting

Unique: with airtight, conditioned and tilting optical boxes for their easy opening

SEA VETRO

THE ULTIMATE GLASS CULLET SORTING MACHINE

Specific: for glass cullet (container, plate or mixed)

Technological: available versions for CSP and metals sorting, color sorting and separation of heat-resistant (HR) glass or glass containing lead oxide.

Precise: equipped with trichromatic RGB cameras. Optical resolution 0,17mm. High rejects concentration

Reliable: thanks to over 40 years' experience

New: launched onto market in 2012

SEA ECHO

THE RESONANCE SORTER

Specific: for nuts (hazelnuts, walnuts, almonds, apricot kernels, pistachios, etc.)

Unique: with resonance sorting technology and chutes feeding

Technological: unequalled efficiency-price ratio, in comparison with IR, Laser or RX sorting technology

Precise: conceived to sort out shells, stones, metals, glass, etc. from kernels

Reliable: thanks to over 40 years’ experience

SEA PIXEL

THE BEST IN THE ESSENTIAL

Flexible: 1 to 5 chutes

Technological: available into monochromatic, NIR, UV versions

Precise: 4 thresholds to control clear and dark sensitivity and for dimensional control of the defects. Optical resolution 0.2mm.

Reliable: thanks to over 40 years' experience

Unique: with tilting optical boxes for their easy opening

SEA NEXT

PASSION FOR DETAILS

Flexible: 1 to 7 chutes divisible in 4 sections

Technological: available into monochromatic, bichromatic InGaAs, NIR and UV versions

Precise: 4 thresholds to control clear and dark sensitivity and for dimensional control of the defects. Optical resolution 0.1mm

Reliable: thanks to over 40 years' experience

Unique: with tilting optical boxes for their easy opening

1970: SEA introduced the first prototype of opto-electronic sorting machine for rice on Italian market. The immediate success led SEA to approach new markets in Europe and to develop sorting machines for other applications, such as nuts, pulses and other dry food and non-food products.

1989: the developed technologies allowed SEA to approach even the recycling industry and, consequently, to realise sorting machines specifically conceived for plastic materials and glass recovery and sorting.

In 2004 the new resonance sorting machine enriches the SEA product range, gaining increasing amounts of approval in the extensive markets.

The latest machine ranges with state-of-the-art technology let SEA have a constantly growing trend in the last years.

SEA technology has actually found its application into several fields, from food industry, to seeds, recycling and mineral ones, representing a fundamental benchmark for a growing number of operators into several Countries.

Since 2012 SEA company has become part of CIMBRIA A/S Danish industrial group of companies, having their headquarters in Thisted, Denmark. With that acquisition, the optical sorting ranges and other electronic solutions will integrate Cimbria mechanical sorting machinery, so completing the working diagram for different products. Thanks to that acquisition, SEA can count on an enhanced and deep-rooted sales net in the international markets, allowing SEA to have a considerable growth both in terms of profits and of new markets penetration.

This is also why, in May 2013, SEA moved its headquarters into a new industrial area of 4500 mq dedicated to production area, laboratories, testing room, offices and management.

New Generation Similago II

REVOLUTION IN MILLING TECHNOLOGY GOES ON...

The new SIMILAGO II is the result of ALAPALA’s 60 years of experience in the technology and engineering of roller mills and the complete range of milling machinery. The SIMILAGO II is designed for high, continuous and consistent grinding of cereals such as wheat, maize (corn), rye, spelt, barley and sorghum. A uniform feed rate across the grinding rolls ensures a consistent grind.

Structurally, the SIMILAGO II has a sturdy frame which is a desk type, precision machined by using the most modern CNC machines. The steel used is a special quality high carbon steel. The bearings and the grinding rolls are directly mounted on to the frame.

This sturdy construction gives the SIMILAGO II the ability to perform high capacity grinding with continuous operation without effecting its performance and reliability day in and day out .

The internal product contact parts are made from stainless steel which also stop the adhering and accumulation of the product and condensation.

The SIMILAGO II is silent in running due to the special profiled transmission belt, drive pulleys and tensioning pulleys which differentially drive the rolls. No greasing is required which provides a clean environment.

Roll temperature is kept low by the air circulation provided by the aero dynamic design of chamber structure.

Arion Purifier

Perfection best describes the ARION purifier.

As a member of the new generation of machines which have evolved over the past 60 years its innovative design and durable construction makes it a highly reliable, efficient and powerful machine for the purification and classification of the semolina in the flour, durum and maize mills.

WORKING PRINCIPLE

The flow rate of the product is adjusted by a gate which provides a perfect distribution of the product along the entire width of the sieves. The ideal vacuum along the sieve surface is obtained by an aerodynamic air canal with regulating valves. This keeps the bran and other light fractions suspended and taken to the discharge and collecting boxes below. The semolina and bran are separated by the sifting action of the sieves. The cleaning of the sieves is done by brushes.

SCOPE OF USE

Machine designed for the removal of fine and coarse impurities from cereal caryopses by sifting action. Due to its adjustable speed and inclinable screen, it can be used as a multilateral grain-cleaning machine.

APPLICATION FIELDS

* At food processing industries

- Flour and semolina mills

- Seed cleaning plants

- Cereals cleaning and calibration centers

- Malt factories

- Feed mills

- Cereal storage silos

* At other similar industrial plants.

STRUCTURE

- Vibrating structure supported by elastic shock-absorbing elements, containing the sifting body with two rows of sieves pairs,

- Self adjusting grain feed,

- Self cleaning of the sieve covers by means of rubber balls,

- Transparent plexiglass panels for checking the cereal strata,

- Steel or wooden made sieve frames equipped with easily replaceable perforated plates

- The vibrator motors, which provides the oscillation for the separator.

WORKING PRINCIPLE

Vibrating process is maintained by means of vibro-motors, which are placed in the center of gravity of the machine. The grain feeding chamber and body which are mounted on the rubber shock absorbers by vibrating together and driven by vibro-motors convey the product into midsection of inlet. The grain is separated uniformly on the entire surface of the screen by means of an adjustable regulating gate.

If it is necessary, for better product flow another adjustable regulating gate can be fixed to the inlet of the screen.

When the grain passes through from the first screen to the second one, larger size impurities or foreign particles are kept by the first screen and directed to coarse offal discharge line. Then, the cleaned product is transported to an air canal or tarar.

SCOPE OF USE

A low pressure and high flow rate radial type fan is used in different industrial sector where the ventilation systems need.

APLICATION FIELDS

-Food industry

-Flour and semolina mills

-Feed mills

-Biscuit and macaroni factories

-Dry fruit plants

-Barley plants

-Tea plants

-Tobacco plants

-Other food industry

-Chemical industry

-Painting made plants

-Plastic made plants

-Deterging made plants

-Wooden industry

-Nonferrous product industry

-Stone and Soil industry

-Cement industry

The low pressure fans provides low pressure in conveying systems and cereal cleaning machines in the cereal processing plants to prevent dust leaking

Flow Balancer - TFBI

SCOPE OF USE

It is used to measure preciously the weight of cereals during flow.

APPLICATION FIELDS-Food industry

The measuring process is carried out by a PLC programme. The programme provides data for product flow, communication between pneumatic controlled caplet and load cell, special inlet spout which can give quick adjusting possibility of very high and very low flow rate. If the automatic dosing machine will run individually, each machine should have its own PLC, in case, they will work as a group, for each group one PLC unit shall be installed. All data are registered in central control room system.

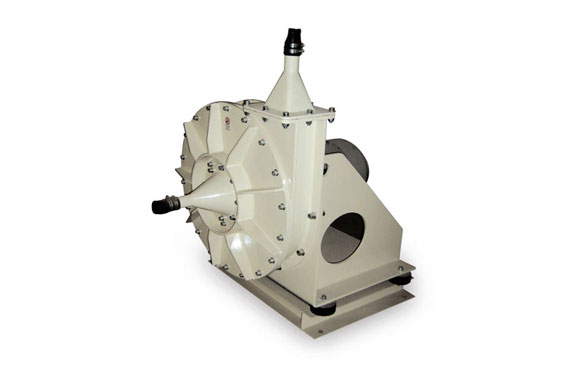

Hammer Mill TCDA

SCOPE OF USE

It is designed to grind the grains.

APPLICATION FIELDS

* At food industry

- At flour mills for offal grinding

- At feed mills for feed grinding and expeller cakes

- At oil mills for extraction of meal, expeller cakes

- At dehaulling (peeling) plants for oat hulls and damaged (broken) rice

WORKING PRINCIPLE

The product is fed regularly into the hammer mill by means of a suitable feeder. The size of particles is reduced by means of a rotor with beaters, which catches the product. The beating process will go on until the particles are flung through the perforated sieve, which surrounds the rotor. Then the product is collected in a hopper.

The hammer mill can be directly installed above a silo so that the product can be directly discharged into the silo. In such case, the silo must be equipped with an aspiration system, at a minimum capacity of 10 cubic meters per minute. To protect the rotor and perforated sieve a powerful magnet ought to be erected before the hammer mill.

Infestation Destroyer for Flour - DVDU

SCOPE OF USE

It is used in the flour mills to prevent infestation of insects to be grown in the processed product.

APPLICATION FIELDS

-At food industry

-Flour mills and semolina mills

-Biscuit and macaroni factories

-Other food industry

WORKING PRINCIPLE

The product is conveyed through center into a blade installed rotor which is at horizontal position. During the rotation movement, the product is thrown to wall of the machine and the grown eggs are destroyed.

Aurora Plansifter

Modular Square Plansifter

The Aurora is a new generation of Plansifter which is designed by using new and innovative concepts of using modules, which allow a total flexibility from 2 sections to 4, 6 and 8 sections to suit the specific requirements of its usage. By using a new manufacturing technique which allows fast delivery times to respect the customer’s demands.

APPLICATION & SCOPE OF USE

The Aurora has been designed to sift and grade granular and floury products in flour mill, maize mill (corn mill), durum, rye and rice mills. It can also be applied for the sorting of free flowing and granular products.

Dry Stoner - TKTA

SCOPE OF USE

It is used to remove stones, mud balls, glass or metal pieces from cereals, leguminous seeds, shelled seeds and similar products.

APPLICATION FIELDS

* At Food Industry

- Flour Mills and Semolina Mills

- Cereal Cleaning Plants,

- Corn Factories

- Oil Factories

- Malt Factories

- Cacao and Coffee Plants

Control Plansifter - RKES

SCOPE OF USE

It is used to fill in the gap between the big plansifter and the laboratory plansifter. Therefore, it provides great advantages. The capacity of the plansifter is determined by taking into consideration the kind of application and the grade of silk cloth.

APPLICATION FIELDS

The unit is strongly advised to be used after product silo before packing of products.

It is widely used in different industrial fields as well:

* At flourmills: for wheat, corn and similar grain processing plants.

* At feed mills: for final sifting of formulated feed meals, corn, crushed pellet feed, barley, oats and for removing the remained coarse materials after grinding and similar processes.

* At various foods processing plants: for sifting process of instant soups, baby food, sugar and tea.

* At others industrial plants: For sifting of plastic, salt and granular materials.

Destoner Classifier - TKTD

SCOPE OF USE

Combined machine for selecting of cereals into light and heavy fraction and for separating the heavy fraction from stones and other particles with high specific weight.

APPLICATION FIELDS

* At Food Industry

- Flour mills and Semolina Mills

- Cereal Cleaning Plants,

- Corn Factories

- Oil Factories

- Malt Factories

- Cacao and Coffee Plants

STRUCTURE

- Alloy steel support structure suspended an elastic shock absorbing elements with adjustable inclination,

- Aluminium tubular frames clothed with spring-steel wire,

- Vacuum operation by means of micrometric aspiration adjustment,

- Inlet and outlet sleeve

- Support plank for aspiration butterfly valve

Air Jet Plus Filter - KFSI

SCOPE OF USE

Suitable to separate dust and other particles suspended in air of cleaning department aspirator system before being discharged to the outside with a bottom scraper.

APPLICATION FIELDS

* At food industry

- Flour and semolina mills

- Feed mills

- Biscuit and macaroni factories

- Nut processing plants

- Brewery factories

* Other food processing plants

* At chemical industry

- Paint factories

- Plastic factories

- Detergent factories

* At wooden industry

* At non-metallic industries

* At stone and soil quarries

* At cement factories

* For general use

Air Recycling Tarar - KTHI

SCOPE OF USE

It is used to eliminate light particles, foreign materials and dust from cereals and vegetable with efficacy and un minimum of air consumption.

APPLICATION FIELDS

* At food industry

- Flour mills and semolina mills

- Corn, barley, rye, oats and similar grain processing plants

- Cereals cleaning plants

- Vegetable oil factories

- Seed plants

- Grain storage silos

* At other similar industrial plants

Bran Finisher - DKFS

SCOPE OF USE

Machine, which uses a centrifugal action to gently separate the floury endosperm, attached to the bran, thus reducing to the minimum the starch content of offal and ensuring high flour yield.

APPLICATION FIELDS

*At food processing industry

-Flour mills

-Semolina mills

Magnet (Tubular Type) - KDMB

SCOPE OF USE

It is used to separate metallic particles from the product.

APPLICATION FIELDS

* At food industry

- Flour mills & semolina mills

- Feed mills

- All grain cleaning plants

- Corn processing plants

- Oil factories

* At plywood factories

WORKING PRINCIPLES

The product enters into a tubular shaped chamber from the inlet, and passes over a magnet. The magnet is opened periodically and metallic particles can be automatically discharged.

Hammer Mill - TCDA

SCOPE OF USE

It is designed to grind the grains.

APPLICATION FIELDS

* At food industry

- At flour mills for offal grinding

- At feed mills for feed grinding and expeller cakes

- At oil mills for extraction of meal, expeller cakes

- At dehaulling (peeling) plants for oat hulls and damaged (broken) rice

WORKING PRINCIPLE

The product is fed regularly into the hammer mill by means of a suitable feeder. The size of particles is reduced by means of a rotor with beaters, which catches the product. The beating process will go on until the particles are flung through the perforated sieve, which surrounds the rotor. Then the product is collected in a hopper.

The hammer mill can be directly installed above a silo so that the product can be directly discharged into the silo. In such case, the silo must be equipped with an aspiration system, at a minimum capacity of 10 cubic meters per minute. To protect the rotor and perforated sieve a powerful magnet ought to be erected before the hammer mill.

Vertical Vibrator Sifter - DVSI

SCOPE OF USE

It is used to unstuck the humid and greasy flour which come from the filter and the bran finisher.

APPLICATION FIELDS

*At food processing industry

-Flour mills

-Semolina mills

Turbo Control Sifter - TKSF

SCOPE OF USE

It is used in the flour mills to separate any foreign material may be mixed into final product during milling process or storage. The foreign materials separated from product before packing, product storage or bulk loading silo.

APPLICATION FIELDS

- Food industry

- Flour and semolina mills

WORKING PRINCIPLE

The product is conveyed into a cylindrical formed perforated sieve and than it is thrown on the sieve wall with a high speed by means of angular blades which are installed on the rotor. When the product is thrown on the perforated sieve on the flour passes through the holes and it is conveyed to flour chamber and passes through the bunker than directed to discharge and bigger size of foreign material will be conveyed to discharging outlet through the internal chamber. hose size is selected beforehand. During the screening process, flour passes through the screen and larger sizes of bran are directed to the discharge outlet.

Pellet Press KPPM

SCOPE OF USE

It is designed to obtain the pressed feed by mixing by - products in the flour mills and product in the feed mills with water, steam or molasses.

APPLICATION FIELDS

-Food industry

-Flour and semolina mills-Feed mills

-Corn, oats, rye, barley and similar grain processing plants

Bucket Elevator - KBEA

SCOPE OF USE

Belted bucket elevator is very ideal for vertical conveying of bulk materials or products, which have particle size up to 50 mm.

APPLICATION FIELD

It is designed to be used for both food and non-food industrial applications.

*At food processing industry

- Flour, semolina and feed mills

- Brewery plants

- Food processing systems

- Coffee and cocoa processing plants

* At chemical and similar plants

* At cement factories

* At fertilizer plants

* At stone and lime plants

* At other similar industrial plants

Pneumatic Line Diverting Gate - KPKA

SCOPE OF USE

It is used to divert the product both for pressurized conveying and for aspirated pneumatic conveying systems.

APPLICATION FIELDS

* At food Industry

- Flour, semolina and feed mills

- Biscuit and pastry plants

- Nut processing plants

- Malt factories

* At chemical industry

- Paint factories

- Plastic plants

- Detergent plants

* Wooden Industry

* Soil plants & Quarries

* Cement factories

* At other similar industrial plants

Pneumatic Fan - DPMA

SCOPE OF USE

It is used to convey granular or ground products in the system where at high pressure and low or medium flow rates are required.

APPLICATION FIELDS

* At food industry

- At flour mills and semolina mills in the cleaning, milling and packing sections

- At feed mills

- At nut processing plants

- Brewery plants

* At chemical industry

- Paint factories

- Plastic plants

- Gas conveying systems

* At wooden industry

* At stone and soil quarries

* At cement factories.